A blank sheet of paper into a manual printing process

Do you know how such a blank piece of paper into a manual, go, today to take you to understand this magical process!

First of all, we have to make the plate according to the customer's demand, check the plate after loading.

And then after a number of adjustments to the plate, printing ink uniformity before printing.

You think this is finished? This is only half finished.

After printing, the paper needs to go through a drying process to ensure that the ink or pigment is completely fixed on the paper to avoid scuffing or color loss.

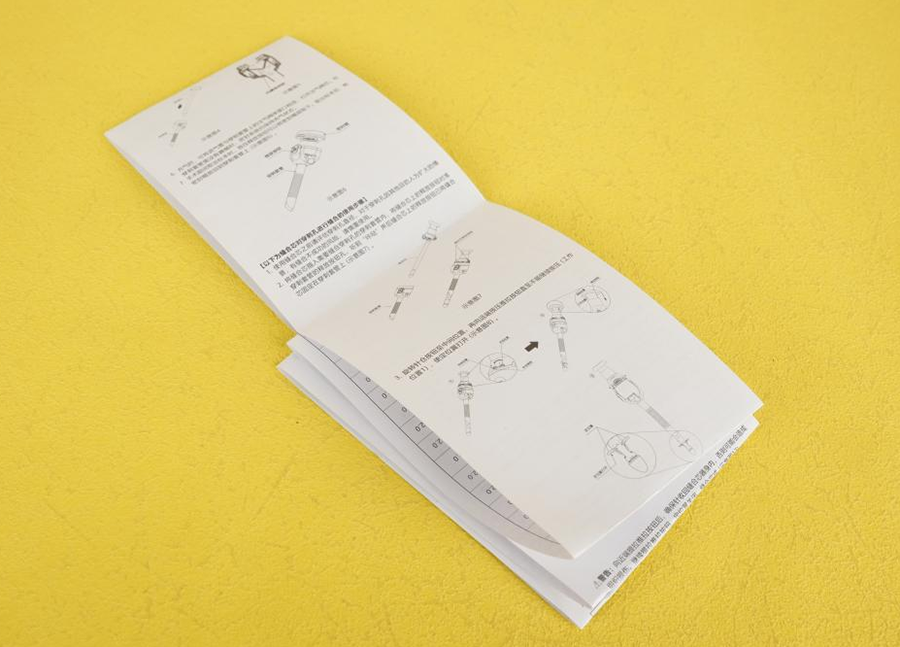

The next step is to put it into the folding machine for folding.

Then after printing and binding is complete, the bound booklet is cut on three sides to bring it to the final size and shape of the instruction manual.

Finally, a quality check is carried out to ensure that the printing quality, content accuracy and appearance of the manual meet the requirements.