Printing Process

Today to introduce a few common printing processes: Relief Printing 、 Lithography and Screen Printing.

Relief Printing

Relief printing means that the graphic portion of the printing plate is higher than the non-graphic portion, and the ink on the ink rollers can only be transferred to the graphic portion of the plate, while the non-graphic portion is free of ink, thus completing the printing of the printed matter.

Lithography

The graphic part of the printing plate and the non-graphic part of the printing plate keep the surface flat, the graphic part is covered with a layer of oil film rich in grease, while the non-graphic part absorbs appropriate moisture. When ink is applied, the graphic portion rejects the moisture and absorbs the ink, while the non-graphic portion absorbs the moisture and forms an ink-resistant effect. The print has the characteristics of thicker ink in the center part of the lines or dots, not neat enough at the edges, poor reproduction of hues, and lack of brightness.

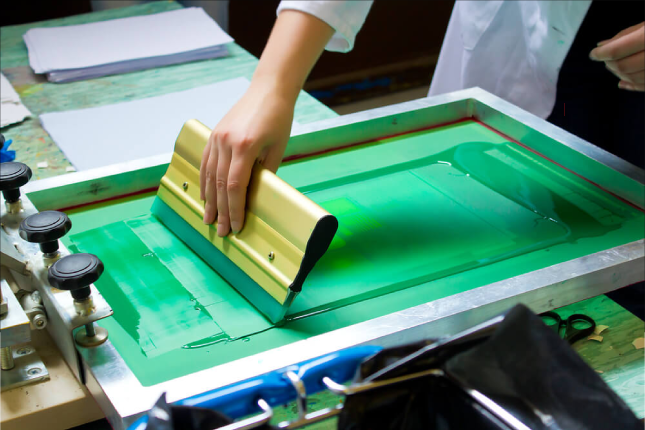

Screen Printing

Screen printing refers to the squeezing action of the squeegee, the ink from the graphic part of the mesh leakage to the substrate, while the non-graphic part of the screen mesh is blocked, the ink can not be leaked to the substrate, so as to complete the printing of the printed matter. The print is rich in texture, three-dimensional sense, and this printing method for the substrate material does not require too much, so it is widely used in a variety of packaging materials.

After the printing is finished and the ink is dry, you can proceed to the next step —— Laminating.