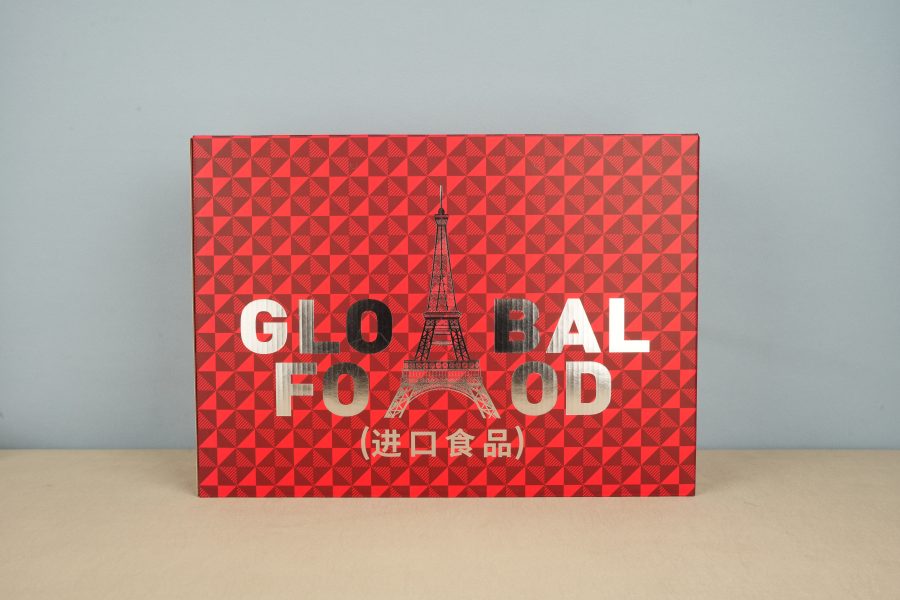

High Quality Foil Stamping Effect, What’s Point Need Attention

If you want get high quality foil stamping effect what should be pay attention to, let go to our factory and check it out.

1, choose the right substrate: hot stamping substrate should be selected texture dense, high smoothness of the paper, so as to obtain a good hot stamping effect, the unique aluminum alloy luster fully embodied.

2, choose good quality hot stamping paper: the quality of hot stamping paper is able to directly affect the effect of hot stamping, good quality hot stamping paper bright colors, high gloss, hot stamping effect is more outstanding.

3, control the stamping temperature: because the temperature is too high may lead to excessive stamping, making the pattern fuzzy; temperature is too low, it leads to stamping is not solid.

4, a reasonable grasp of the stamping pressure: stamping pressure and aluminum adherence fastness has a great relationship, too much pressure may damage the substrate, the pressure is not enough will lead to stamping is not firm. So in the stamping, should be carefully adjusted stamping pressure, to ensure that the pressure is uniform.

5, with advanced stamping equipment and skillful operation skills, only then can ensure the precision and quality of stamping.

In order to get the ideal hot stamping effect and quality, we need to consider these factors and make appropriate adjustments and control in actual operation.